What is SeedJection™ and how does it work?

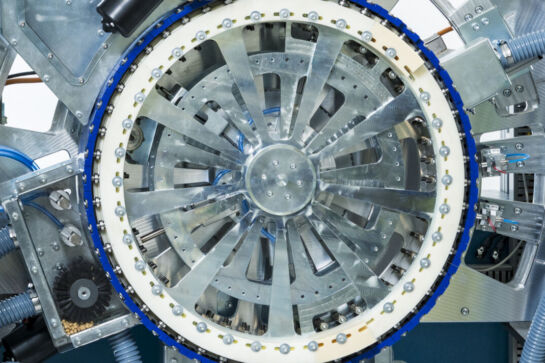

SeedJection™ is our patented technology that injects beneficial microbes directly into the seed’s interior. In contrast to conventional seed coating, the living microorganisms stay viable and active inside the seed’s protective structure to support germination.

Why are microbes important for agriculture in the first place?

Microbes play a vital role in healthy plant growth. They help roots absorb nutrients, fix nitrogen, protect against disease, and support soil fertility. In nature, plants rely on these microscopic partners every day. Harnessing them in agriculture means working in balance with the ecosystem.

Is the SeedJection™ process safe for the seed and the environment?

Yes. SeedJection™ injects microbes directly into the seed without damaging its structure or disrupting its natural microbiome. This way, the need for synthetic agrochemicals is reduced to support a more sustainable and environmentally friendly approach to crop production.

Is your technology already being used in the field?

SeedJection™ has been successfully tested in field trials across multiple locations and is already in use for soybean seed treatment in commercial settings. The technology has proven its performance under real conditions—from germination and microbial viability to yield outcomes.

Does SeedJection™ work for every crop and with a wide range of microbial strains and formats?

Currently optimized for soybean, SeedJection™ is being adapted for maize and other crops. The system is compatible with a broad range of microbial formulations, including strains that are difficult to stabilize by means of conventional methods.