Ensemo changes farming forever by putting biology, not chemistry, at the center of growth. Starting from the premise that every single seed encloses an entire future ecosystem, we created SeedJection™ to unlock nature’s full potential. It is the first technology to place beneficial microbes exactly where they belong—inside the seed itself.

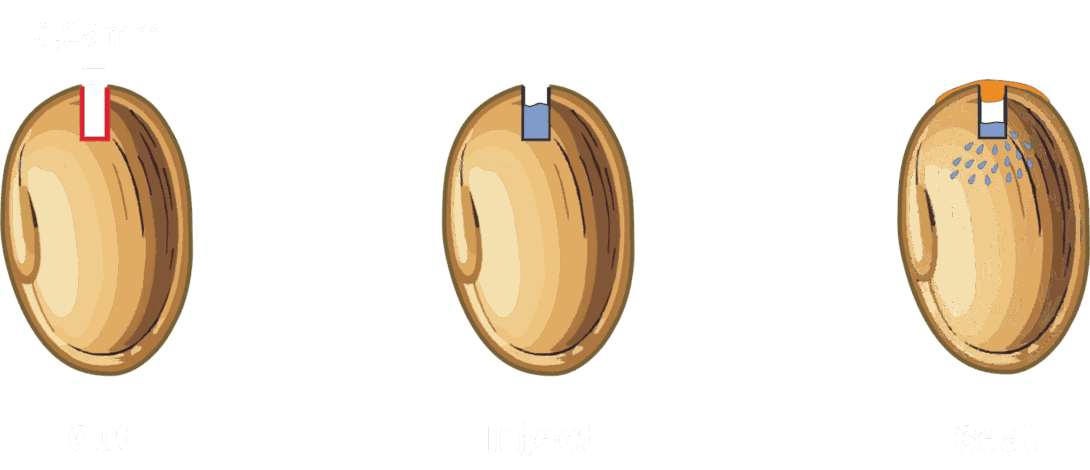

Through a microscopic opening, we gently introduce living microorganisms directly into the seed’s core. Unlike surface coatings that wash away, dry out, or lose efficacy, SeedJection™ protects microbes under the seed’s natural armor. This way, the microbes stay viable, active, and effective when it matters most: in the field, under real conditions.

Our machines guarantee a smooth process without damaging the embryo or reducing germination. They work at high throughput, treating thousands of seeds per second.

Since 2018, SeedJection™ has transformed from a bold vision into a robust, fully operational technology. What started as a hand-crafted prototype has evolved into a modular high-capacity system for industrial use.

Housed in 40-foot containers, it is transportable across continents and scalable to meet the demands of modern global seed production.

We develop our machines from laboratory models into industry-ready systems, ensuring consistent precision and robust performance throughout. Our industrial prototypes deliver the same high accuracy as our lab-scale system. While we are driving soybean seed treatment today, we are retooling for maize, as well as a broader range of crops and biologicals, tomorrow.

The agricultural revolution starts long before a

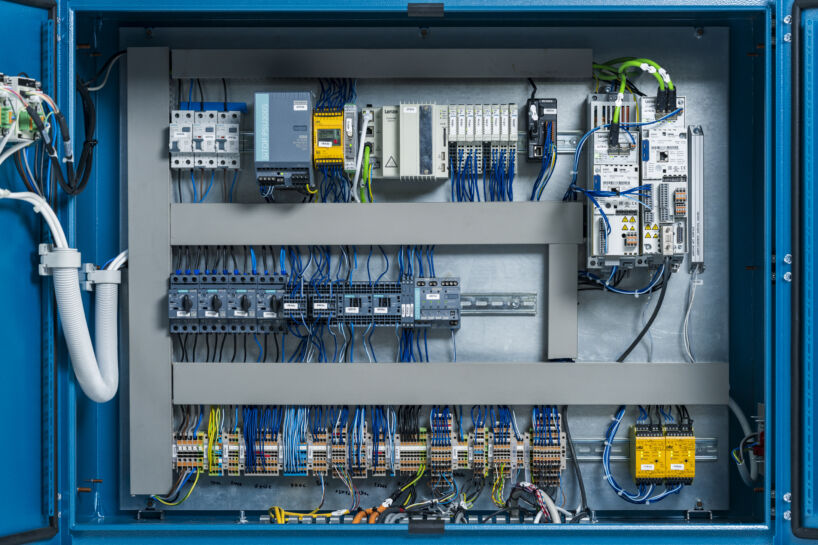

machine touches a seed. At Ensemo we understand that every bolt, every weld, and every circuit matters to make a change.

Our components are sourced from specialized suppliers, designed to endure the mechanical and environmental stresses of high-throughput seed treatment. Each SeedJection™ machine is assembled with exacting tolerances. Mechanical structures, sensor systems, and micro-injection units are integrated step-by-step.

As we prepare for scaled production, quality assurance is our focus: critical parts are inspected individually in every SeedJection™ machine; each subsystem is validated before integration; upon assembly, endurance is tested under near-operational conditions for reliable performance.

How We Build SeedJection™

- Precision sourcing

- High-accuracy assembly

- In-process quality control

- Pre-delivery endurance testing

From the laboratory to the warehouse, from the sowing to the harvest, Ensemo has undertaken severe investigation to validate SeedJection™. In sum, we tested thousands of soybean seeds, across different varieties following the ISTA protocol and received clear results: compared to untreated seeds, SeedJection™ treatment maintained—and in many cases even improved—germination rates with an average increase of 4%.

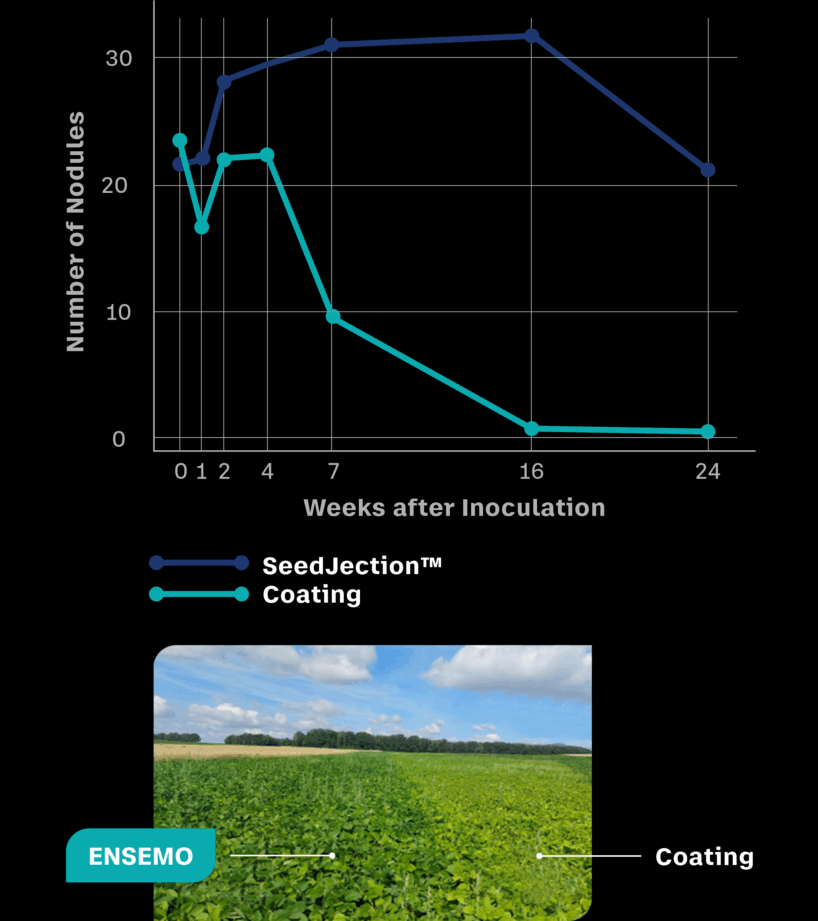

In terms of viability, seeds treated with SeedJection™ were stored for over six months under commercial conditions. They showed microbial vitality persisting. Rhizobia populations, injected and sealed inside the seed, remained stable and ready to perform up to 24 weeks after traditional surface treatments would have failed.

Finally, we brought our proof to the field. Across large-scale trials, SeedJection™-treated seed matched the agronomic performance of conventional on-farm inoculation. The decisive benefit of those seeds: greater consistency, less effort, and no last-minute handling.